Reading time: 6 min

There are many techniques for personalising your merchandise or goodies.

How to know which one is the most suitable based on your expectations?

Each technique has its advantages and disadvantages, it's crucial to understand them well to make the best choice. Whether you want to make a short series of very colourful t-shirts or a large series of t-shirts with a single-colour design, there is always a more suitable solution that will allow you to optimise the cost of your merch.

To help you choose, we will present machine embroidery, screen printing, digital marking, screen transfer, and pad printing.

Machine embroidery

Embroidery is one of the first computer-aided manufacturing techniques. It is considered the most noble and high-end textile marking technique with its relief, pleasant touch sensation, robustness, and durability. Obviously, this superior quality requires a higher price than other techniques like screen printing. You can choose a design with as many colours as you want without affecting the price, but it's important to know that gradients cannot be achieved. It's the size of the area to be embroidered that will determine its cost, whether higher or lower. That's why we use it for patches, caps and polo shirts.

The technical part: The machine is controlled by a computer, it has a system that keeps the area to be embroidered taut. The computer automatically moves this area according to the programmed design.

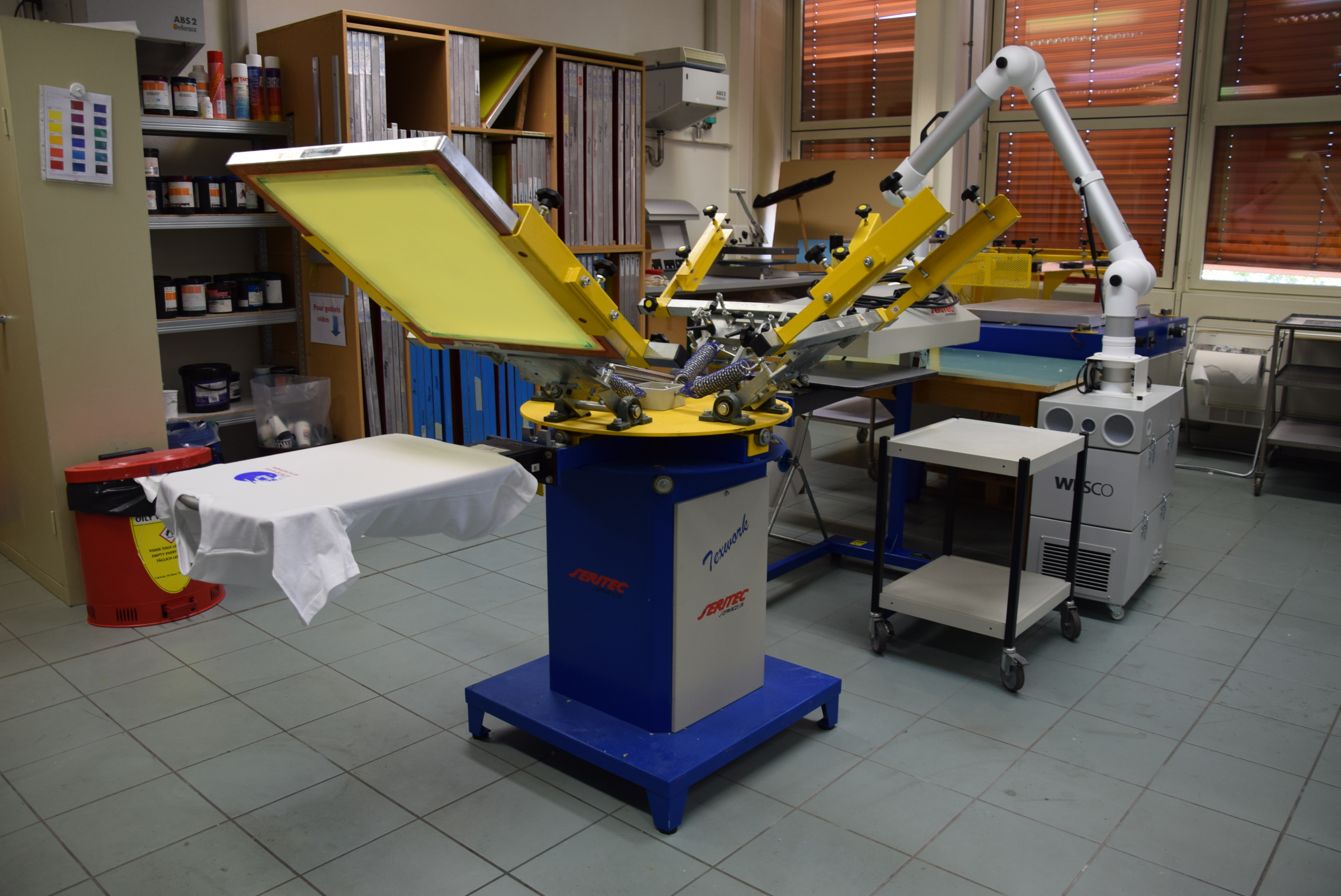

Screen printing

Screen printing is one of the oldest textile marking techniques derived from stencilling that we use for personalising t-shirts, sweatshirts, patches and tote bags. It involves printing a design by superimposed colour layers, so the more colours in the design, the higher the cost. It's therefore one of the most cost-effective techniques for large series with designs using few colours while maintaining impeccable quality and a pleasant touch. Another constraint to consider is that to fix the colour, the ink must be exposed to a high temperature, so it is advised to use this technique only on textiles composed mainly of cotton.

If you want more information about the screen printing process, you can find more in our article: The essential of merchandising: textiles.

Direct to garment (DTG) or digital marking

Digital marking is the most recent technique. We directly print the design on the t-shirt with a high-definition inkjet printer. The ink absorbed by the fabric leaves a smooth, uniform, and matte impression. For dark fabrics, we first print a white undercoat to preserve the brightness of the colours. This constraint makes direct printing more expensive on dark fabrics. This technique is only suitable for fabrics composed of at least 70% cotton. It allows printing detailed, precise, and realistic coloured designs with gradients but is more cost-effective for smaller series.

Screen transfer

Screen transfer is a mix between the classic transfer technique, which is more consumer-oriented and thus less qualitative, and screen printing. It involves screen printing a transfer sheet and hot-pressing it onto a garment, regardless of its material, leaving a thin, pleasant-to-touch design. The fabric colour doesn't influence the transfer cost since the design is glued onto it, however, the number of colours in the design does influence the cost as the sheet is screen printed. Since the fabric isn't impregnated with ink, the marking is less durable in the long term than classic screen printing. Screen transfer is therefore less cost-effective for large series as it requires screen printing each transfer sheet individually, which then needs to be glued to the t-shirt, adding an extra step in the t-shirt personalisation compared to screen printing. The result, however, remains of good quality, with fine details and impeccable contours.

Pad printing

Pad printing is the preferred personalisation technique for goodies. Indeed, it allows marking any type of surface quickly and at low cost using a pad, whether for large or small series. However, it has some constraints. It is not recommended to pad print flexible or textile surfaces. As this technique is not the most precise, it is not the most suitable for screening or marking designs with multiple colours.

Some technical details: The pad leaves a thin layer of ink. This ink takes more or less time to dry depending on the surface. It is not recommended to put pad-printed goodies in the dishwasher as it may alter the design.

In summary

Here's a summary table to help you understand the difference between each marking technique. Don't hesitate to consult it before placing an order to ensure you make the most suitable choice. In any case, at Distrolution Merch, we always advise you before launching production to ensure you're completely satisfied with your order. If you want to share these tips with your friends, don't hesitate to share this article on social media!

| Personalisation techniques | Advantages | Disadvantages |

|---|---|---|

| Embroidery |

High-end Pleasant to touch Robust |

Higher price Cannot be done on all types of materials Does not allow for gradients |

| Screen printing |

Economical for large series with one or two colours Pleasant touch Durable |

The more colours, the higher the cost Expensive for small series Especially suitable for 100% cotton products |

| Digital marking |

Very smooth touch, no relief Cost-effective for designs with nuances Allows printing gradients Suitable for small series |

Higher price than screen printing, especially for large designs Higher price for dark textiles |

| Screen transfer |

Allows marking different types of materials (cotton, polyester) No additional cost for dark textiles Low thickness, therefore pleasant to touch |

Higher cost depending on the number of colours Less durable than screen printing Higher cost than screen printing for large quantities |

| Pad printing |

Preferred technique for goodies Perfect for single-colour designs Fast and economical |

Not suitable for textiles Monochrome marking Not recommended on flexible material objects |